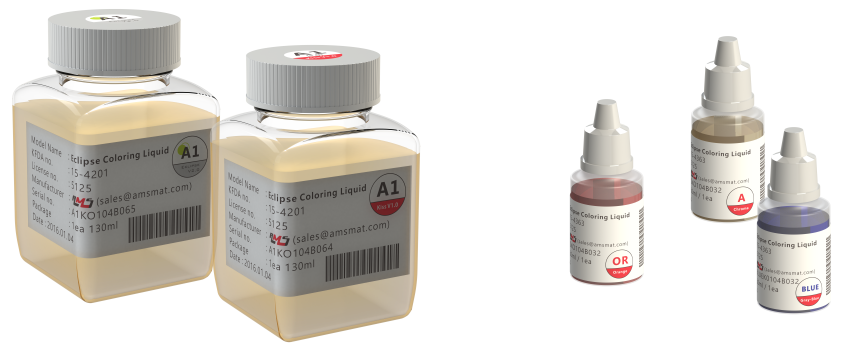

LIQUID

ECLIPSE Coloring Solutions

AMS also has coloring liquids for ECLIPSE (Kiss) zirconia disks.

| MENU | EFFECT |

| A1 – D4 | Dipping or Brushing for Vita 16 shades. |

| 3D Master | Dipping or Brushing for selected 3D Master colors. |

| Gray-Blue | Grayish blue color. Available for different concentration. |

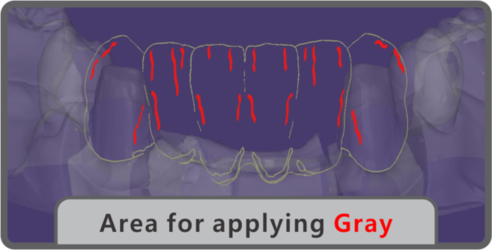

| Gray | Gray color. Available for different concentration. |

| G (gradation) | To increase Hue, apply G before dipping or brushing other colors. |

| O (Occlusal) | To increase Hue, apply O before dipping or brushing other colors. / O has very weak gray color |

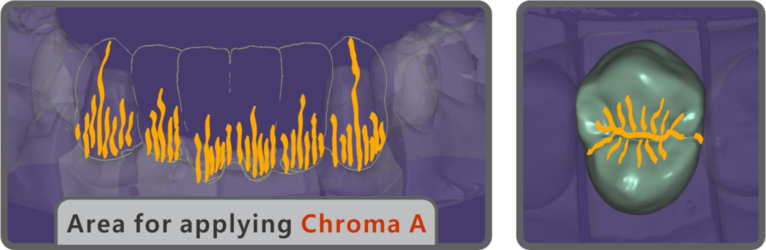

| Chroma A | To enhance vita A series colors. Strong. |

| Chroma B | To enhance vita B series colors. Strong |

| Chroma C | To enhance vita C series colors. Strong |

| Cervical A | To enhance vita A series colors. Moderate |

| Cervical B | To enhance vita B series colors. Moderate |

| Cervical C | To enhance vita C series colors. Moderate |

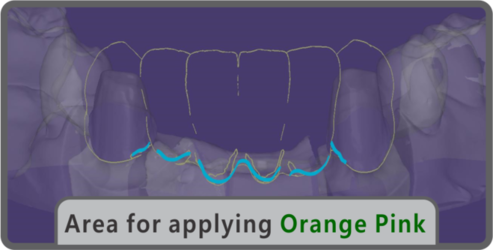

| Orange Pink | Strong Pinkish Orange color |

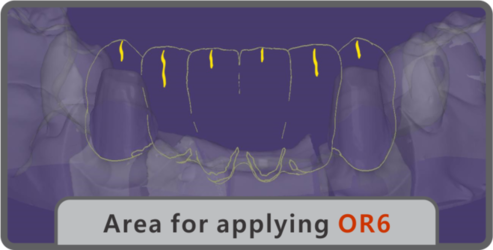

| OR 6 | Strong Orange color |

| W.O. (White Opaque) | Strong White paint. Very Opaque |

| Pink | Moderate Pink color |

| Violet | Strong Violet color |

| Emerald | Strong Green color. |

| Diluent | To reduce a concentration of other colors. |

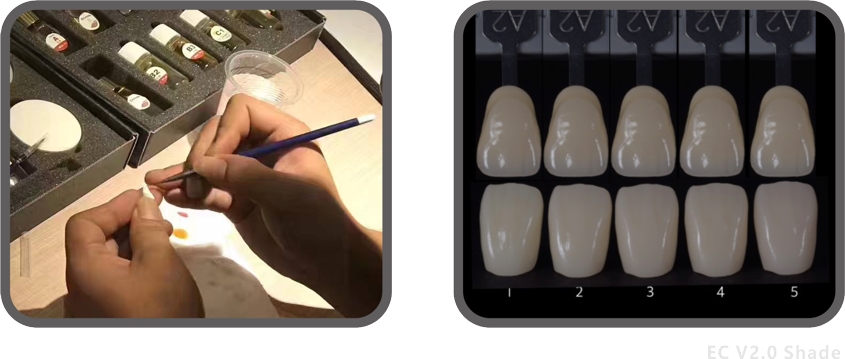

SHADING

6 shades are compatible with Vita 16 shades. These water base coloring liquids are good for dipping or brushing method.

Other effect color liquids have to use brushing method. AMS knows that matching the right colors are very important to make customers satisfy. AMS will work to find right colors, you only need to choose the colors.

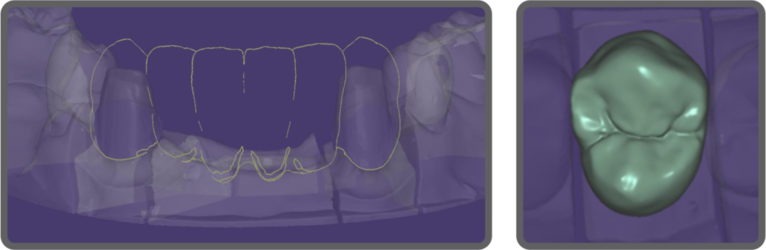

Instructions for AMS zirconia coloring

– Examples of using coloring liquids

Prepare Coloring liquids

Effect: It has Light gray-blue color and increase a translucent effect.

Effect: It has very light gray color. It prevents to absorb the dipping liquids and increase Hue.

Effect: It has gray color and increase a translucent effect

Effect: It has very darker than A4 color and can be applied for increasing Chroma on cervical area. Chroma B and Chroma C have similar effect.

Effect: It has strong Orange color.

Effect: It has orange pink color and can be applied on edge of cervical.

Effect: It prevents to absorb the dipping liquids and increase Hue.

You may skip some special liquids if you fill enough. Before applying special colors, you need to have drying step. After applying special colors, dry completely then dipping into appropriate dipping liquids (A1-D4) for 8-10 seconds.

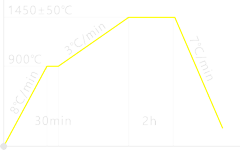

Sintering temperature of EC 2.0 and Kiss 1.0 is 1450℃ Sintering temperature of EC 2.0 plus and Kiss 1.0 plus is 1400℃ These sintering temperatures promise to have optimized results.